Hydraulic Filters

Subcategories

-

Hydraulic Filter Bases

Hydraulic filter bases provide a secure and reliable mounting point for filters, ensuring a leak-free seal and optimal filtration performance in demanding applications.

Use our Cross Reference or Part Finder Tool to find filters for your machinery.

-

Hydraulic Breather...

Prevent contaminants from entering your hydraulic system with our breather filters, allowing air exchange while blocking dirt and moisture.

Use our Cross Reference or Part Finder Tool to find filters for your machinery.

-

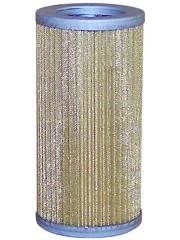

Hydraulic Filter Elements

Our hydraulic filter elements provide efficient removal of particles, keeping your hydraulic fluid clean and your equipment running smoothly.

Use our Cross Reference or Part Finder Tool to find filters for your machinery.

-

Hex Nut Hydraulic Filters

Hex Nut hydraulic filters are designed for easy installation and removal, providing reliable filtration for heavy-duty machinery.

Use our Cross Reference or Part Finder Tool to find filters for your machinery.

-

Hydraulic Filters...

Monitor the condition of your hydraulic filters with built-in indicators that provide real-time information, ensuring timely filter replacements and system protection.

Use our Cross Reference or Part Finder Tool to find filters for your machinery.

-

In-Line Hydraulic Filters

In-line hydraulic filters offer compact and efficient filtration, preventing contaminants from entering sensitive hydraulic components and improving system reliability.

Use our Cross Reference or Part Finder Tool to find filters for your machinery.

-

Spin On Hydraulic Filters

Spin-on hydraulic filters are easy to replace and provide high-efficiency filtration, making them ideal for maintaining clean hydraulic systems in agricultural and industrial machinery.

Use our Cross Reference or Part Finder Tool to find filters for your machinery.

-

Hydraulic Filters with...

Hydraulic filters with springs ensure a secure fit and consistent filtration pressure, optimising performance even in high-vibration environments.

Use our Cross Reference or Part Finder Tool to find filters for your machinery.

-

Suction Strainer...

Suction strainer hydraulic filters protect pumps by filtering contaminants before they enter the hydraulic system, ensuring longer pump life and smoother operation.

Use our Cross Reference or Part Finder Tool to find filters for your machinery.

-

Hydraulic Breather...

Hydraulic breather filter caps provide dual protection, allowing air to flow into the system while filtering out contaminants, ensuring clean hydraulic fluid.

Use our Cross Reference or Part Finder Tool to find filters for your machinery.

-

Return Filter Tank Top...

Return hydraulic filters mounted on tank tops provide efficient filtration of returning fluid, ensuring contaminants are removed before the fluid re-enters the system.

Use our Cross Reference or Part Finder Tool to find filters for your machinery.